Luoyang Yujie Industry&Trade Co., Ltd is one of the most experienced manufacturers and suppliers of floor type boring machine in China. Please feel free to buy cheap floor type boring machine for sale here from our factory. All customized products are with high quality and competitive price.

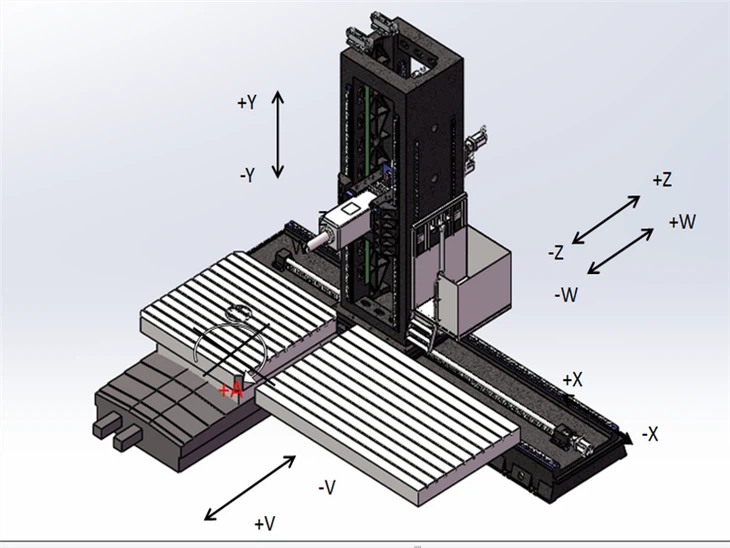

Products Description

A floor type boring machine is a type of machining equipment used for drilling, boring, and machining large and heavy workpieces. It is typically used in industries like aerospace, automotive, and energy where precision and accuracy in machining large components are essential.

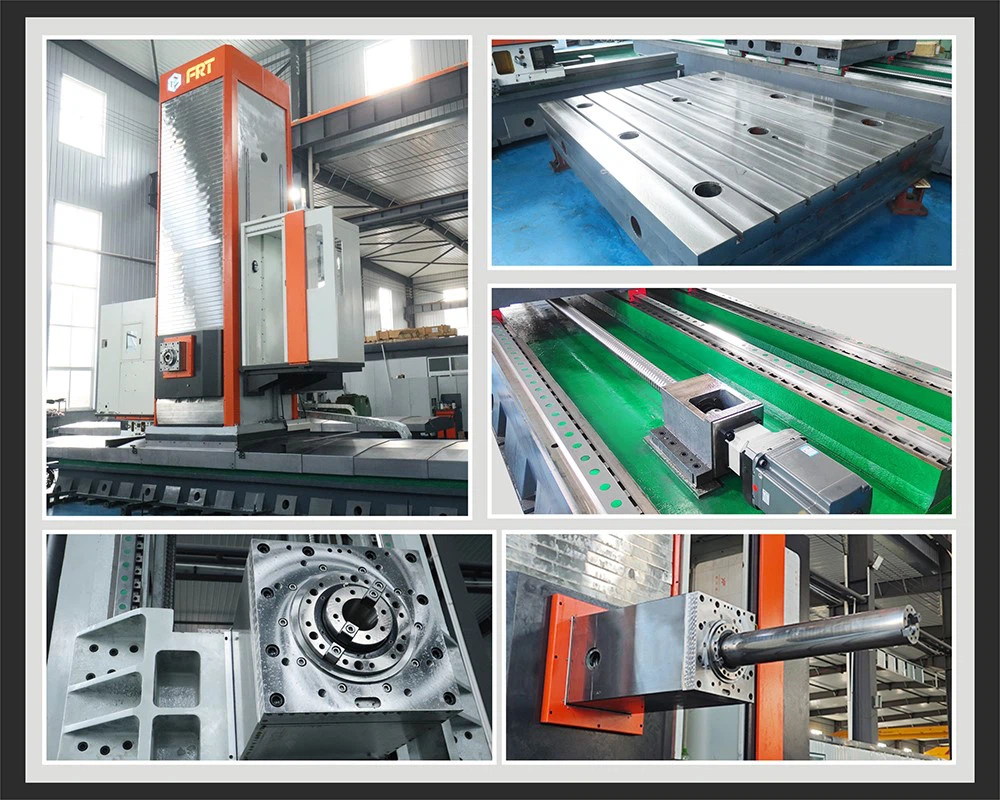

Casting processing

| Technical specification | FRT-T130 | FRT-T160 | FRT-T200 | |

| Travel | ||||

| Work table travel(X/Y/Z/W) | mm | X (4000-6000) | X (6000-8000) | X (8000-10000) |

| mm | Y (2000-3000) | Y (2000-3000) | Y (2000-3000) | |

| mm | Z (800) | Z (1000) | Z (1200) | |

| mm | W (700) | W (1000) | W (1200) | |

| Distance from spindle surface to worktable | mm | 0-3000 | 0-3000 | 0-4000 |

| Guide rail | Two linear guide rail, one hardened rail | |||

| Work table | ||||

| Table size | mm | Customization | Customization | Customization |

| The maximum load capacity of the work table | T | 15/㎡ | 15/㎡ | 15/㎡ |

| Spindle | ||||

| The spindle taper(model sleeve diameter) | BT50 | BT50 | BT50 | |

| The spindle motor power | kw | 26 | 35 | 45 |

| Spindle speed | rpm | 2000 | 2000 | 2000 |

| Accuracy | ||||

| Position Precision | mm | 0.01/1000 | 0.01/1000 | 0.01/1000 |

| Repeated position precision | mm | ±0.01 | ±0.01 | ±0.01 |

| Size | ||||

| Net weight | T | about 55~70 | about 90~130 | about 125~165 |

options

precision components of floor type boring machine

Spindle:

The spindle is the main rotating component that holds the cutting tool.

High precision spindles with minimal runout contribute to accurate hole machining.

Spindle speed and power are critical for different machining applications.

Tool Changer:

CNC floor borers often have an automatic tool changer (ATC) that allows for the efficient and quick exchange of cutting tools.

Precision in tool change mechanisms is essential to maintain accuracy and reduce downtime.

Linear Guides and Bearings:

Linear guides and bearings ensure smooth and precise movement of the machine components along the axes.

High-quality linear motion systems contribute to accuracy in positioning and repeatability.

Ball Screws:

Ball screws are used for translating rotational motion from the motor to linear motion in the axes.

Precision ball screws reduce backlash and contribute to the overall accuracy of the machine.

Control System:

The CNC control system is the brain of the machine, interpreting programmed instructions and translating them into precise movements.

High-resolution encoders and accurate feedback systems are crucial for maintaining precision.

Axis Drives:

Servo or stepper motors drive the movement along different axes.

Precise control of these motors is essential for accurate positioning and movement.

Tool Measurement and Calibration Systems:

Automated systems for tool length measurement and tool calibration contribute to precision by ensuring accurate tool offsets.

Coolant and Lubrication Systems:

Efficient coolant and lubrication systems help maintain the temperature and reduce friction, contributing to both tool life and machining accuracy.

Bed and Frame Rigidity:

The rigidity of the machine bed and frame is critical for minimizing vibrations and ensuring stability during machining operations.

Cutting Tool Quality:

The quality and sharpness of the cutting tools directly impact the precision of the machining process.

Software and Programming:

CNC programming and simulation software play a crucial role in creating accurate toolpaths and optimizing machining parameters for precision.

Feedback Systems:

Feedback systems, such as encoders and sensors, provide real-time information to the control system, allowing for corrections and adjustments to maintain precision.

characteristics of floor type boring machine

Size and Structure: Floor type boring machines are large and robust machines designed to handle massive workpieces. They are constructed with a heavy-duty, horizontal structure that rests on the shop floor.

Horizontal Boring: These machines are capable of performing horizontal boring operations, which involve drilling or machining holes in a horizontal direction along the X and Y axes.

Versatility: They can accommodate a wide range of workpiece sizes and shapes, making them suitable for machining large and complex components, such as engine blocks, turbine casings, and industrial equipment.

High Precision: Floor type boring machines are known for their high precision and accuracy, making them suitable for critical applications where tight tolerances must be maintained.

CNC Control: Most modern floor type boring machines are equipped with CNC (Computer Numerical Control) systems. This allows for precise control over the machining process, including tool movements and cutting parameters.

main functions of floor type boring machine

Boring: The primary function of a floor type boring machine is to bore holes into workpieces. It can create both small and large-diameter holes with high accuracy.

Drilling: These machines can perform drilling operations to create holes of various sizes and depths in the workpiece.

Milling: Some floor type boring machines are equipped with milling capabilities, allowing them to perform milling operations to shape and finish workpiece surfaces.

Facing: Floor type boring machines can face the ends of workpieces to ensure they are flat and perpendicular to the bore holes.

Tapping: In some cases, these machines can also be equipped with tapping capabilities to thread holes.

Contouring: With CNC control, floor type boring machines can follow complex toolpaths to create intricate shapes and contours on the workpiece.

suitable workpieces for floor type boring machine

Engine Blocks: Floor type boring machines are commonly used to machine engine blocks in the automotive industry. They can bore cylinders, drill holes, and create precise mating surfaces for various engine components.

Turbine Casings: These machines are used in the energy sector to machine turbine casings for power generation equipment. They can create complex internal and external features while maintaining tight tolerances.

Large Gears: Floor type boring machines are suitable for machining large gears used in heavy machinery and industrial equipment. They can create gear teeth and ensure proper alignment.

Hydraulic Cylinder Housings: Machining hydraulic cylinder housings requires precision, and floor type boring machines are well-suited for this task. They can create smooth and accurately sized cylinder bores.

Aerospace Components: In the aerospace industry, floor type boring machines are used to machine structural components, such as wing spars and landing gear components, which demand high precision and consistency.

Shipbuilding Components: These machines are employed in shipbuilding to create precise holes and bores in large structural elements, like ship frames and bulkheads.

Molds and Dies: Floor type boring machines can be used to machine large molds and dies for the plastics and metalworking industries, ensuring that intricate shapes and features are accurately produced.

Mining and Construction Equipment: Components for heavy machinery in mining and construction, such as bulldozer frames and excavator parts, can be machined with precision using these machines.

Large Valves and Pumps: Floor type boring machines are used to machine components for the oil and gas industry, including valves and pumps, which require precise internal features.

Wind Turbine Components: In the renewable energy sector, these machines are employed to machine large parts for wind turbines, such as gearboxes and tower sections.

FAQ

Q: Are you trader or factory?

Q: What kind of service can you provide?

Q: Will weld inspection and paint thickness inspection be performed?

A: Yes. We also support third-party testing.

Hot Tags: floor type boring machine, manufacturers, supplier, factory, customized, cheap, price, in stock, for sale