The technological process of the Segmented Gear Ring/Girth Gear

Following step:

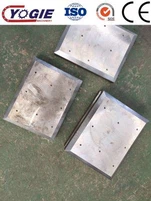

Making wooden mold -Smelting and casting -Cooling model -Cleaning and Polishing -Annealing treatment -Joint face rough machining and drilling -Connecting the whole parts - Rough turning - UT Qualified - Quenching and tempering -Separate the parts and joint face fine milling - Connecting the whole parts - Fine turning - Tooth Machining (Tooth milling or hobbing) - Drilling and Tapping - Tooth surface hardening - Deburring - Final Inspection - Oil coating and painting - Packing and delivery.

Segmented gear rings/girth gears are used to drive large rotary systems, such as dryers, rotary kilns, horizontal mills.

Yogie is a professional manufacturer for the customized processing of large, heavy, non-standard machinery parts and non-standard complete sets of equipment processing and assembly.

Do you have any specific questions about the design or manufacture ? Contact Yogie!

Welcome to visit us. We will enjoy give you the best service.