Luoyang Yujie Industry&Trade Co., Ltd is one of the most experienced manufacturers and suppliers of helical gear rack and pinion in China. Please feel free to buy cheap helical gear rack and pinion for sale here from our factory. All customized products are with high quality and competitive price.

Products Description

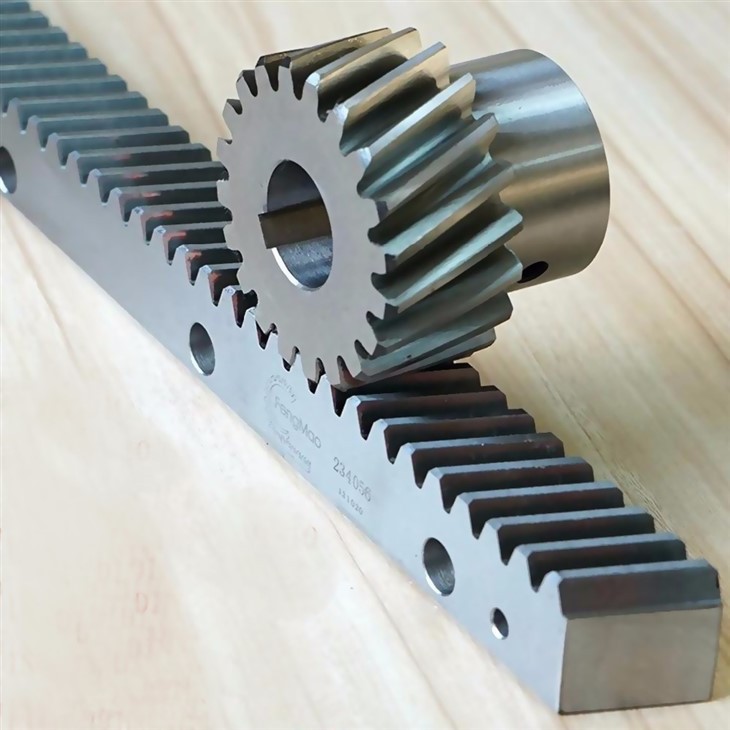

A helical gear rack and pinion system is a type of mechanical arrangement used to convert rotational motion into linear motion or vice versa. It consists of two main components: a helical gear (pinion) and a toothed bar (rack). These components work together to transfer motion and power between perpendicular axes.

features of helical gear rack and pinion

Helical Gear (Pinion):

The pinion is a cylindrical gear with helical teeth that are cut at an angle to the gear's axis.

Helical teeth resemble twisted lines around the gear, providing smoother engagement compared to straight-cut gears.

The helix angle allows for gradual tooth engagement, reducing noise and vibrations during operation.

Helical gears distribute the load more evenly across the teeth, leading to improved load-carrying capacity and efficiency.

Gear Rack:

The rack is a straight, toothed bar that meshes with the helical gear's teeth.

The teeth on the rack are also helically cut to match the angle of the gear's teeth.

The rack's teeth engage with the pinion's teeth, translating the rotational motion of the pinion into linear motion along the rack's length.

functions of helical gear rack and pinion

Motion Conversion:

The primary function of a helical gear rack and pinion system is to convert rotational motion into linear motion or vice versa.

When the pinion rotates, its helical teeth engage with the rack's teeth, causing the rack to move linearly along its length.

This linear motion can be used for various purposes, such as moving machinery components, controlling positioning systems, and converting rotary input into linear output.

Precision and Control:

The helical design of the teeth allows for smooth and gradual engagement, reducing impact and noise during operation.

This smooth engagement is particularly useful in applications requiring precise positioning and controlled movements, such as CNC machines, robotic arms, and automation systems.

Load Distribution and Efficiency:

Helical gear rack and pinion systems distribute the load evenly across a larger area of teeth compared to straight-cut gears, leading to higher load-carrying capacity.

The helical teeth design also improves power transmission efficiency by minimizing backlash (play between teeth) and reducing wear and tear.

Versatility and Applications:

Helical gear rack and pinion systems find applications in a wide range of industries, including manufacturing, automotive, aerospace, and more.

They are used in scenarios where precise linear motion control is required, such as in CNC machining, cutting equipment, conveyor systems, and steering systems in vehicles.

Summary

Overall, helical gear rack and pinion systems offer improved efficiency, smoother operation, and better load distribution compared to straight-cut gears. They play a crucial role in various mechanical applications that demand accurate and controlled linear motion.

Hot Tags: helical gear rack and pinion, manufacturers, supplier, factory, customized, cheap, price, in stock, for sale, Bearing seat