Luoyang Yujie Industry&Trade Co., Ltd is one of the most experienced manufacturers and suppliers of high precision brick-making machine mould in China. Please feel free to buy cheap high precision brick-making machine mould for sale here from our factory. All customized products are with high quality and competitive price.

High precision brick-making machine mould

Products Description

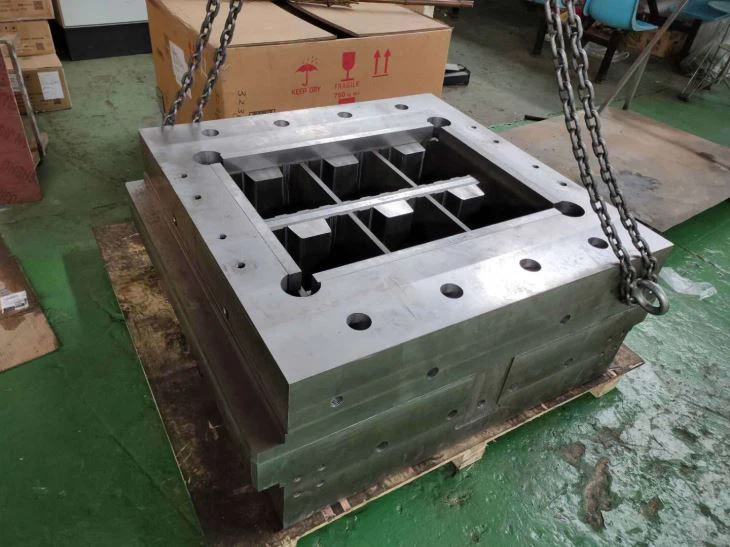

A brick-making machine mold is a component of a brick-making machine designed to shape raw materials, such as clay or concrete, into specific brick forms. It determines the size, shape, and texture of the bricks produced. The mold is a crucial element for creating uniform and high-quality bricks, and its features include durability, customization, and ease of maintenance. Its primary function is to facilitate the compression of raw materials to form compact bricks, and it finds applications in various construction projects for producing bricks, paving blocks, and specialized architectural features.

Features

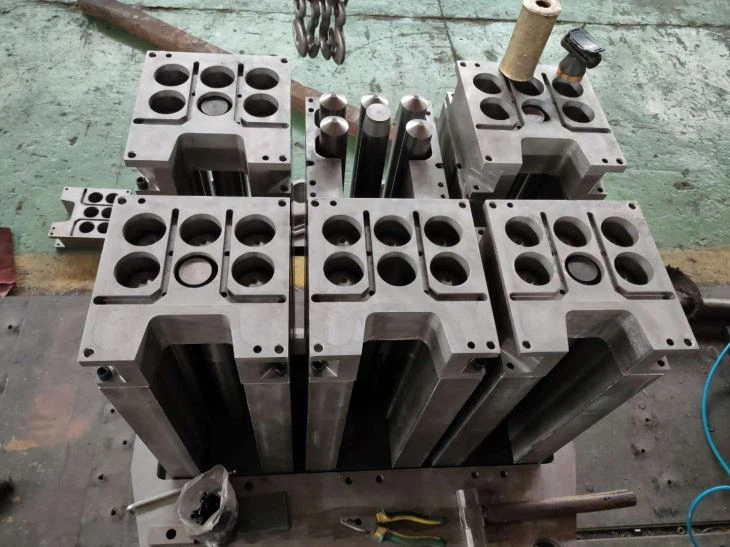

Material: Molds are typically made from materials that can withstand the pressures and temperatures involved in the brick-making process. Common materials include cast iron, steel, or special alloys.

Customization: The molds are designed to create bricks of specific dimensions and shapes. They can be customized based on the requirements of the project or the desired characteristics of the bricks.

Durability: A good mold should be durable to withstand the repeated impact and pressure during the brick-forming process. The material and construction of the mold should ensure a long lifespan.

Ease of Maintenance: Molds should be designed for easy maintenance, allowing for quick and efficient cleaning and repairs as needed. This helps in ensuring the longevity of the mold and the quality of the bricks produced.

Precision and Consistency: The design and manufacturing of the mold must ensure precision and consistency in the size and shape of the bricks produced. This is essential for creating uniform and high-quality bricks.

functions

Brick Formation: The primary function of the mold is to shape the raw material (usually a mixture of clay, sand, and other additives) into the desired brick form.

Compression: The mold facilitates the compression of the raw material to form a compact and cohesive brick. This is often done through the application of pressure, either manually or through automated processes.

Release Mechanism: The mold should have a mechanism for easy removal of the formed brick. This could involve a hinge or other release features to ensure that the brick can be easily extracted without damage.

Texture and Surface Finish: Some molds are designed to impart specific textures or surface finishes to the bricks. This can include smooth surfaces, rough textures, or patterns depending on the mold design.

applications

Brick Manufacturing: The primary application of a brick-making machine mold is in the production of bricks. These bricks can be used for various construction purposes, including building walls, pavements, and other structures.

Paving Blocks: In addition to traditional bricks, molds can be designed to produce different types of paving blocks or interlocking bricks used in landscaping and pavement applications.

Architectural Features: Specialized molds can be used to create bricks with unique shapes and textures, allowing for the production of bricks used in architectural detailing.

Industry-Specific Bricks: Depending on the industry requirements, molds can be designed for the production of bricks with specific properties, such as high strength or resistance to certain environmental conditions.

others

Mould is used in industrial production for injection molding, blow molding, extrusion, die casting or forging molding, smelting, stamping and other methods to get the required products of various molds and tools. In short, a mold is a tool which is used to make molding objects. This tool consists of various parts. Different molds are made of different parts.Used in automobile industry, bending machine, etc.

advantages

Product advantages

1 mould clamping accuracy is high

2 good surface finish

3 Product quality stability

4 long service life

Company advantages

1.20 years of experience in processing mould

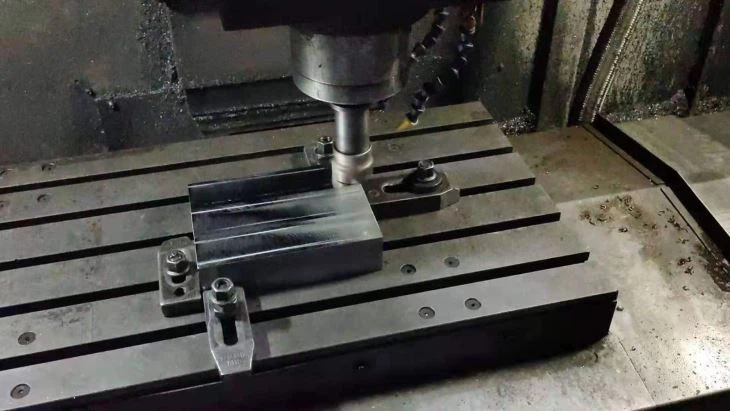

2.Large-size Heavy-Duty CNC vertical lathe

3.Large-size casting,production capacity 800 tons each time

4. Providing customers for a series of service and key solutions from roughcasting to finished products.

Hot Tags: high precision brick-making machine mould, manufacturers, supplier, factory, customized, cheap, price, in stock, for sale, Auto mold parts, auto parts, Bearing seat, space military mold