Luoyang Yujie Industry&Trade Co., Ltd is one of the most experienced manufacturers and suppliers of 35crmo wind turbine shaft in China. Please feel free to buy cheap 35crmo wind turbine shaft for sale here from our factory. All customized products are with high quality and competitive price.

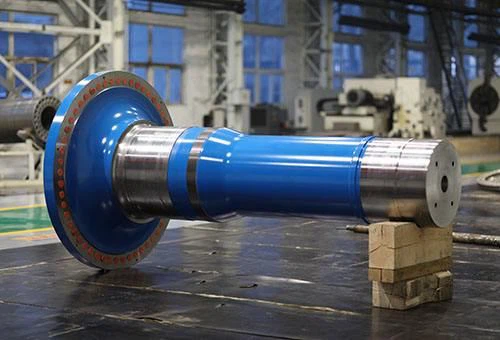

35CrMo wind turbine shaft machined on 6m horiqontal machine tool equipment

Products Description

A wind turbine shaft is a long cylindrical component of a wind turbine that rotates when wind blows on the blades of the turbine. The shaft connects the blades to the generator, which converts the rotational energy into electrical energy.

The shaft is typically made of steel and can be several meters long, depending on the size of the wind turbine. It is designed to withstand high stresses and loads caused by the rotational forces of the blades and the weight of the generator.

The wind turbine shaft rotates at high speeds and must be well lubricated to reduce friction and wear. It is supported by bearings that allow it to rotate freely.

main features of wind turbine shaft

Material: Wind turbine shafts are typically made from high-strength materials to withstand the mechanical stresses and fatigue caused by continuous rotational movement and varying wind conditions. Common materials used include high-strength steel alloys or composite materials.

Length and Size: The length and diameter of the shaft depend on the size and capacity of the wind turbine. Larger turbines designed for higher energy output will generally have longer and thicker shafts to handle the increased loads.

Design: The shaft is designed to provide optimal balance between strength, weight, and flexibility. It needs to be strong enough to handle the loads generated by wind forces and the rotor's rotational motion while remaining lightweight to reduce unnecessary inertia.

Bearings and Mounting: The shaft is equipped with bearings at various points along its length to support the rotor's weight and facilitate smooth rotation. The bearings help reduce friction and wear as the shaft rotates.

Couplings: The shaft is often connected to the gearbox or transmission system of the wind turbine. Flexible couplings are used to connect components while accommodating slight misalignments and absorbing vibrations.

Dynamic Loads: Wind conditions are variable, which results in dynamic loads being applied to the turbine shaft. These loads can include aerodynamic forces from changing wind speeds and directions, as well as mechanical loads from the rotor's mass and rotation. The shaft must be designed to handle these dynamic loads without failing prematurely.

Fatigue Resistance: The continuous rotation of the wind turbine exposes the shaft to cyclic loading, which can lead to fatigue failure over time. Proper material selection and design are crucial to ensure the shaft's long-term reliability.

Maintenance and Accessibility: Wind turbine shafts need to be designed with maintenance and accessibility in mind. This includes considerations for inspection, lubrication, and potential replacement.

Corrosion Protection: Since many wind turbines are located in outdoor environments, the shaft's surface is often treated to resist corrosion, especially if it's made of steel.

Environmental Considerations: In recent years, there has been increasing emphasis on environmentally friendly materials and practices in wind turbine construction, including shaft design. Sustainable materials and manufacturing processes are becoming more common.

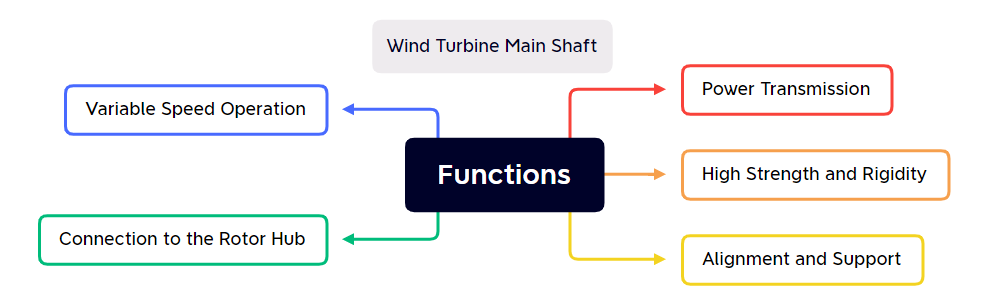

The functions of the wind turbine main shaft

A wind turbine shaft, also known as a wind turbine main shaft, is a critical component in a wind turbine system. It plays a crucial role in converting wind energy into electrical energy. Here are the key functions and characteristics of a wind turbine shaft:

Description

Power Transmission: The primary function of a wind turbine shaft is to transmit the rotational power generated by the rotor blades to the generator. As the wind hits the blades, it causes them to rotate, and this rotational motion is transferred to the main shaft. The main shaft, in turn, transmits this mechanical energy to the generator, where it is converted into electrical energy.

High Strength and Rigidity: A wind turbine shaft needs to have high strength and rigidity to withstand the significant forces and torque applied to it. The shaft must endure the rotational forces generated by the rotor blades and the weight of the rotating components. Typically, wind turbine shafts are made of high-strength materials such as alloy steel or carbon fiber composites to ensure durability and structural integrity.

Alignment and Support: The wind turbine shaft is supported by bearings at various points along its length. These bearings help maintain the proper alignment of the shaft and minimize friction losses during rotation. Proper alignment is critical to ensure efficient power transmission and to prevent excessive wear on the components.

Connection to the Rotor Hub: The wind turbine shaft is connected to the rotor hub, which holds the rotor blades. This connection can be achieved through a flange or other suitable means. The rotor hub transfers the rotational motion from the blades to the shaft, allowing the energy conversion process to take place.

Variable Speed Operation: Many modern wind turbines are designed for variable speed operation, where the rotational speed of the rotor is adjusted to optimize energy capture from the wind. In such systems, the wind turbine shaft may include additional components like a gearbox or a direct-drive system. These components help adjust the rotational speed of the generator to match the wind conditions and maximize power output.

Summary

Overall, the wind turbine shaft is a critical component that enables the conversion of wind energy into electricity. Its strength, alignment, and connection to the rotor hub are vital for efficient power transmission and the reliable operation of the wind turbine system.

The machinery processing of the wind turbines main shaft

Raw material: Forging step,we design the best forging blank to reduce the raw material cost,thus save money for customer.

Rough machining: Leave enough allowance for further production

UT Test: to check if there is any internal defect.According to this way,we make sure our raw material is qualified.

Heat Treatment: To adjust the hardness and improve the mechanical property.

Shaft Grinding--Surface roughness is Ra 0.8, ensure a high accuracy. easy for the assembly of bearing and shaft ,also work together well.

Hole drilling:to the drawing size

Packing and delivery :The products should be processed to be rustproof and moisture proof before delivery.

Applications

Wind turbine shafts play a critical role in the functioning of wind turbines. They are responsible for transmitting the mechanical power generated by the wind turbine's rotor to the generator, where it is converted into electrical energy. Here are some applications of wind turbine shafts:

Power Transmission: The primary function of a wind turbine shaft is to transmit the rotational energy from the turbine's rotor to the generator. As the rotor spins, the shaft transfers the torque to the generator, enabling the conversion of mechanical energy into electrical energy.

Speed Regulation: Wind turbine shafts can also be used to regulate the rotational speed of the turbine. By adjusting the gear ratio between the rotor and generator, the shaft can control the rotational speed and optimize it for efficient power generation under different wind conditions.

Mechanical Load Handling: Wind turbine shafts are designed to withstand high mechanical loads and stresses. They need to be strong and durable to handle the forces generated by the wind, especially during strong gusts or turbulent conditions. The shafts ensure the safe and reliable operation of the turbine by transferring these loads without failure.

Alignment and Support: The shafts are responsible for maintaining proper alignment between the rotor and the generator. They provide support and stability to the rotating components, ensuring smooth and efficient power transmission. Proper alignment reduces vibration, minimizes wear and tear, and improves the overall performance and lifespan of the wind turbine.

Integration with Other Components: Wind turbine shafts are designed to facilitate the connection of various components within the wind turbine system. They are typically coupled with gearboxes, bearings, and other mechanical parts to form a complete transmission system. The shafts allow for the efficient transfer of power and torque between these components.

Maintenance and Repair: Wind turbine shafts can also be used as access points for maintenance and repair activities. They provide a convenient means for technicians to inspect and service other components within the turbine, such as the gearbox or the generator. By disassembling the shaft, maintenance tasks can be performed more easily and efficiently.

Overall, wind turbine shafts are crucial for the proper functioning, power transmission, and structural integrity of wind turbines. They enable the conversion of wind energy into electrical energy and ensure the reliable operation of these renewable energy systems.

About us

Luoyang Yujie Industry &Trade Co.Ltd located in Luoyang City, one of the main heavy industrial bases in China. We specialize in the production of nonstandard machinery parts and machine tools. For the nonstandard machine parts, we can produce gears, shafts, sprockets, molds, rollers, pulley, mining machine parts, etc as per customer drawing and requirements.

Contact us

Do you have any specific questions about the shafts? Contact Yogie! Our sales engineers will work with you from start to finish to ensure that your project is completed to your requirements.

![]()

tel: +86-379-65163600

![]()

phone: +86-15036387078

![]()

envelope: sales@yujieindustry.com

![]()

fax:+86-379-65163600

![]()

address:No.9, Sanxi Road, Jianxi Industrial Park, Luoyang City, Henan, China 471003

![]()

whatsapp: 8615036387078

Hot Tags: 35crmo wind turbine shaft, manufacturers, supplier, factory, customized, cheap, price, in stock, for sale