Luoyang Yujie Industry&Trade Co., Ltd is one of the most experienced manufacturers and suppliers of high presure briquetting machine in China. Please feel free to buy cheap high presure briquetting machine for sale here from our factory. All customized products are with high quality and competitive price.

High Presure Briquetting Machine

Products Description

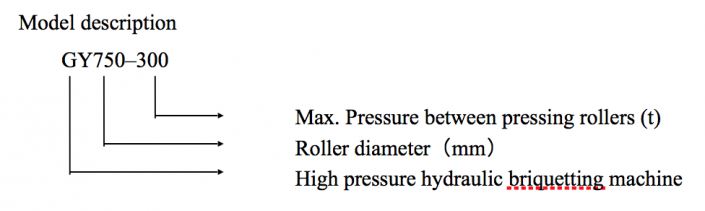

High-pressure briquetting machine

A high-pressure briquetting machine, also known as a high-pressure roller press or briquetting press, is a type of mechanical equipment used to press various powdery materials into briquettes. This machine uses high pressure to compress and shape the raw materials into compact and consistent briquettes, which can be used for various purposes.GY high pressure briquetting machine is a kind of pelletizing machine which can feed various kinds of dry and wet powder through the preliminary pressure device compulsorily into the roll press area and make into high bulk density ball. It is mainly applied in the coal, mining, metallurgy, fire-resistant materials, construction materials and other light metal industries.

Parameters & Componets

| Model | Roller dia. | Roller width | Total pressure | Max. line specific pressure | Main motor power | Capacity | Weight |

| (mm) | (mm) | (t) | (t/cm) | (kw) | (t/h) | (t) | |

| FRT520-150 | 520 | 196 | 150 | 8 | 55 | 2.2-3.5 | 13.7 |

| FRT650-220 | 650 | 205 | 220 | 11 | 90 | 4-6.5 | 19.2 |

| FRT750-200 | 750 | 320 | 200 | 6 | 110 | 7--10 | 24.5 |

| FRT750-300 | 750 | 280 | 300 | 11 | 185 | 6-8.5 | 34 |

| FRT800-380 | 800 | 350 | 380 | 11 | 200 | 8--10 | 39.3 |

| FRT1000-350 | 1000 | 460 | 350 | 8 | 250 | 10--15 | 50 |

| FRT1000-450 | 1000 | 500 | 450 | 9 | 280 | 14--17 | 58.5 |

| FRT1000-500 | 1000 | 500 | 500 | 10 | 315 | 15-20 | 58.5 |

| FRT1000-500 | 1000 | 900 | 450 | 5 | 280 | 25-30 | 63 |

| FRT1000-540 | 1000 | 900 | 540 | 6 | 185×2 | 30-35 | 59.3 |

| FRT1200-800 | 1200 | 900 | 800 | 8 | 280×2 | 40 | 110 |

| FRT1400-1000 | 1400 | 1000 | 1000 | 10 | 355×2 | 50 | 156 |

The functions of briquetting machine

The high pressure briquetting machine is mainly used for ball forming of colored and ferrous metal ore powder, and directly into the furnace for smelting to increase the added value. Any metallurgical industry waste, auxiliary materials need to be on the furnace, all need high pressure ball machine to complete. Such as quicklime, dust ash, sewage, oxide scale, steel slag, iron fine powder, aluminum ash powder, silico-manganese ore powder, and so on.

The newly developed high pressure ball press machine of our factory has obtained the national patent, and the pressure can be increased several times. The important structure is that the original feed is basically converted into a three-way feed. The main roller and the secondary roller are pressed to compact the hemisphere, and the two hemispheres compacted with the rotation of the main roller are fed in the middle, and a second press is performed, thereby multiplying the pressure. The machine has obvious effects on loose materials, such as coke powder, oxide scale, dust ash, sludge, etc., and the effect is extraordinary.

How the briquetting machine typically work

►Raw Material Preparation: The first step involves preparing the raw material. This can include grinding, pulverizing, or shredding the material into a fine powder or suitable form for briquetting.

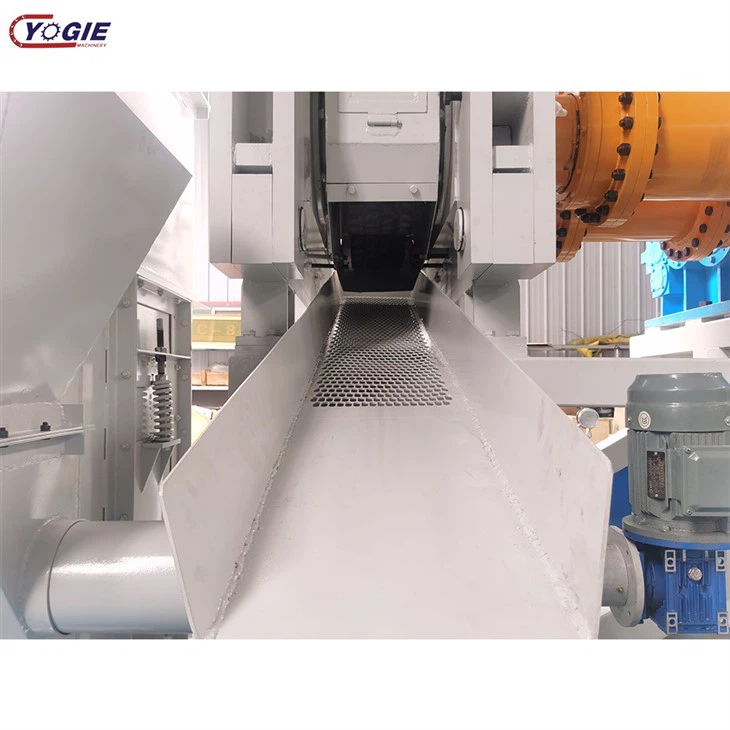

►Feeding System: The prepared raw material is then fed into the high-pressure briquetting machine through a feeding hopper or conveyor. The machine usually has a screw or paddle feeder to ensure a consistent and uniform feed.

►Compression Chamber: The raw material enters the compression chamber, where it encounters two counter-rotating rolls or a roll and a die. These rolls exert high pressure on the material, forcing it to pass through the narrow gap between them.

►Briquette Formation: As the material passes through the compression zone, the high pressure and compacting force cause the powder particles to fuse together. The heat generated during this process helps to bind the particles, forming solid briquettes.

►Briquette Discharge: The formed briquettes are discharged from the machine through a discharge chute or conveyor belt. They can be collected and further processed or transported for storage or use.

Work Principle of briquetting machine

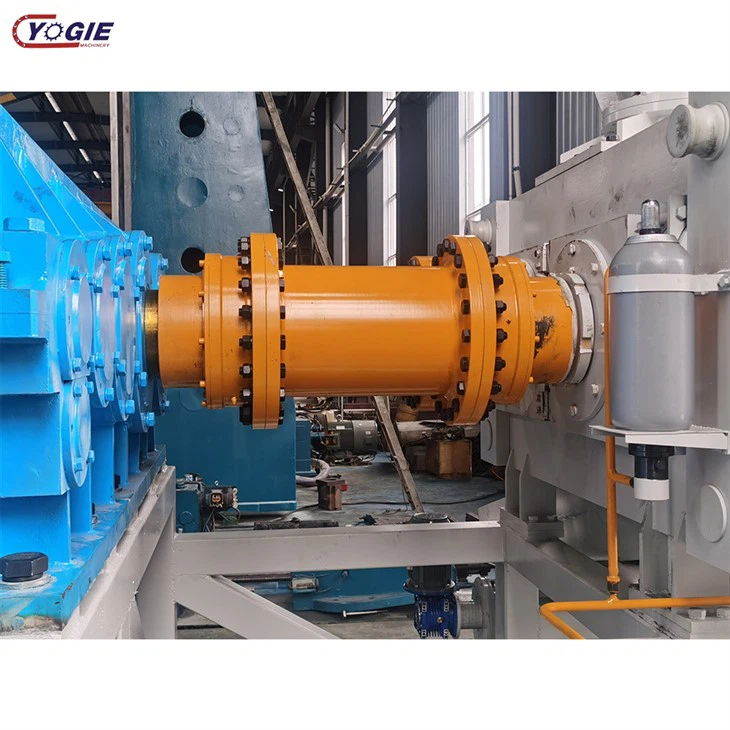

The main body of the high pressure ball press machine is powered by an electromagnetic speed regulating motor, which is transmitted to the drive shaft through a pin and pin coupling through a pulley and a cylindrical gear reducer. The drive shaft and the passive shaft ensure synchronized operation through open gears. The passive bearing housing is equipped with hydraulics at the rear. The screw feeding device of the high pressure ball press is driven by the electromagnetic speed regulating motor, and is rotated by the pulley and the worm reducer to force the pressed material into the main feeding port. Due to the constant moment characteristic of the electromagnetic speed regulating motor, when the amount of material of the screw feeder is equal to the amount of material required by the main machine, a constant supply pressure can be maintained to stabilize the pellet mass. If the feeding amount is too large, the feeding device is overloaded; if the feeding amount is too small, the ball is not formed. Therefore, the skilled operation technique is an important condition for ensuring the normal operation of the ball. The high pressure ball press mainly uses a hydraulic pump to drive high pressure oil into the hydraulic cylinder to cause axial displacement of the piston. The front joint of the piston rod is placed on the bearing housing to meet production pressure requirements. When the feed between the two pressure rollers is too much or enters the metal block, the hydraulic cylinder piston rod is under pressure overload, the hydraulic pump will stop, the accumulator will buffer the pressure change, the relief valve will open the oil return, and the piston rod will be displaced. The gap between the pressure rollers is increased to allow the hard objects to pass through the pressure roller, and the system pressure returns to normal, so that the pressure roller can be protected from damage. The machine can adjust the pressure according to the requirements of the pressure ball density, and the production is flexible.The company has formed three series, more than twenty models after many years of research, tests, and improvements. The structure, performance, quality and service life of products have reached world-advanced level. Our plant can confirm the process flow, process parameters and finish model-selecting, design and manufacturing of briquetting machine based on the test that raw materials are provided by users. Our plant is the production base in China, providing the most complete and latest briquetting machine.

Advantages and Features of briquetting machine

►Raw materials can be pressed well with high ratio of briquetting and high strength of pressed briquettes;

►Better application result of roller surface, longer service life; Adopting the structure of dual-output shaft reducer, improving the roller precision, using hard

►Surface gear to improve the working performance and service life;

►Pre-presser adopts the speed-adjusting motor;

►All wear-out parts are welded with wearing-resistance alloy to improve working performance and service life;

►Hydraulic plant is placed independently with the function of pressure-adjusting and protective function when overloading.

The parts of briquetting machine and Specifications

1.Motor 2. Coupling 3. Gear box 4. Coupling 5.Frame 6. Pre-pressing 7.Belt conveyor

8 Fixed roller 9. Movable roller 10.Cylinder 11. Hydraulic station

About us

Luoyang Yujie Industry &Trade Co.Ltd located in Luoyang City, one of the main heavy industrial bases in China. We specialize in the production of nonstandard machinery parts. For the machine tools, we offer CNC vertical machine center, CNC horizontal lathe, CNC gantry boring and milling machine, CNC floor type boring, and milling machine.

Contact us

Do you have any specific questions about the design and manufacture of the Briquetting Machine or Ball Press Machine ? Contact Yogie!Our sales engineers will work with you from start to finish to ensure that your project is completed to your requirements.

![]()

tel: +86-379-65163600

![]()

phone: +86-15036387078

![]()

envelope: sales@yujieindustry.com

![]()

fax:+86-379-65163600

![]()

address:No.9, Sanxi Road, Jianxi Industrial Park, Luoyang City, Henan, China 471003

![]()

whatsapp: 8615036387078

Hot Tags: high presure briquetting machine, manufacturers, supplier, factory, customized, cheap, price, in stock, for sale