Introduction

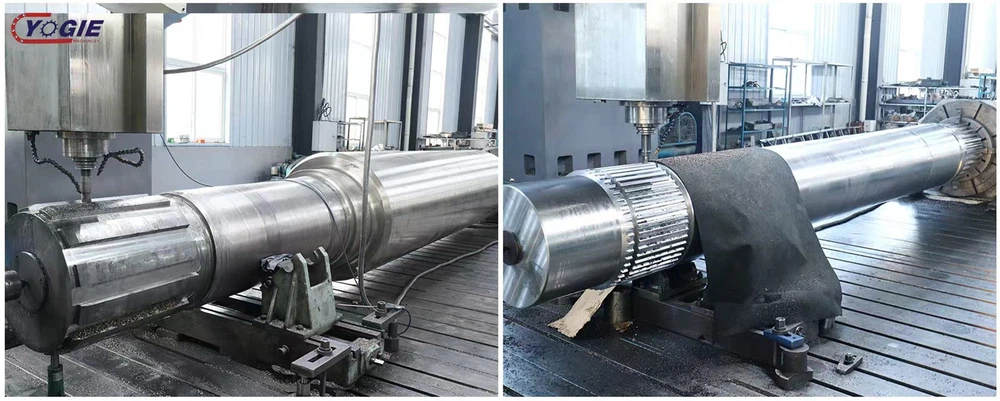

A shaft is a mechanical component used to convey motion, torque, or bending moment. Each of its segments may vary in diameter and serve largely to support transmission components, drive torque, and transport weights. This article will go through the shaft material in depth, with a focus on what material to utilize for the shaft.

A shaft is a mechanical part that usually has a circular cross-section. It provides an axis of rotation for various mechanical components (such as sprockets, gears, pulleys, and cams) fixed to it, and it is used to control the geometry of the motion as it rotates.

Axles are not to be confused with axles, in fact, by definition, an axle is actually a non-rotating member that does not carry torque, but is used to support wheels and other rotating objects. A car axle is not a real axle, but an axle by definition. When analyzing a real axle, you just see that it is a static beam, and then perform a static analysis on it. On the other hand, a dynamic analysis of the shaft is also required to determine the fatigue stress.

What material is used for the shaft?

Common materials for shafts are high quality carbon steel 35, 45 and 50. For lightly loaded shafts, plain carbon steel, such as Q235 or Q275, is also commonly used. Design calculations can begin with inexpensive low-carbon or medium-carbon steels. If it turns out that strength is the main factor controlling deflection, you should try to use stronger materials to reduce the size of the shaft until excessive deflection is a problem. There are also some shafting material (steel grades) options: commonly used stainless steel materials are 430, 304 and 316 and so on. Type 430 and other 400-series stainless steels are stainless steels, while Types 304, 316 and other 300-series stainless steels are non-magnetic and can be strengthened by cold working.

As mentioned above, the materials of the shaft are mainly carbon steel and alloy steel. Most steel shaft blanks use rolled steel and forgings, while others use straight round steel. For the shaft that needs more force, the size and weight of the shaft are limited, and there are some special requirements, alloy steel can be used, commonly used carbon steel grades 40Cr, 45C8, 40MnB, 40CrNi, 50C4, 50C12 are used as shaft materials .

Some commonly used stainless steels are: 430, 304 and 316. Type 430 and other 400 series stainless steels are all stainless steels. Type 304, 316 and other 300 series stainless steels are not magnetic and can be strengthened by cold working. Stainless steel can be heated and cooled in a process called "annealing". This is also known as the "hard and soft" state. Used under higher loads or shocks, "cold working" can be an economical means of reducing weight and increasing strength. 430 steel has little potential for corrosion. Type 304 is mainly used for low humidity and temperature. Type 316 is used when corrosion resistant stainless steel is required.

What criteria should be considered when selecting shaft materials?

There are many types of shaft materials, and the selection is mainly based on the strength, stiffness, wear resistance and other requirements of the shaft, as well as the heat treatment method used to achieve these requirements, and the manufacturing process to be selected at the same time. There are two main criteria to consider when selecting a shaft material. These are strength and stiffness. Stiffness is related to the Young's modulus of the material, while strength is determined by the yield strength and ultimate strength of the selected material.

First, let's talk about stiffness. As mentioned above, stiffness is a function of the Young's modulus of a material. Today, Young's modulus is essentially constant for most steel materials. This means that if steel is chosen as the shaft, the stiffness of the shaft does not depend on the Young's modulus, but on the geometry of the shaft.

Most of the load on the shaft will be perpendicular to the axis of the shaft. This means that beam analysis will be required to calculate the total deflection of the shaft. However, in some cases there will also be axial forces on the shaft. For example, if a thrust bearing is used. Finally, most shafts require twisting because they are used to transmit torque from one component to another.

This article mainly introduces what material is used for the shaft. By reading this article, we can understand that the shaft is usually a mechanical part with a circular cross-section. It provides the axis of rotation for various mechanical components (such as sprockets, gears, pulleys, and cams) fixed to it, and it is used to control the geometry of the motion as it rotates.

contact us

Do you have any specific questions about the Shafts? Contact Yogie! Our sales engineers will work with you from start to finish to ensure that your project is completed to your requirements.

Tel: +86-379-65163600

Fax: +86-379-65163600

Mobile: +86-15036387078 (whatsapp / wechat)

Email: sales@yujieindustry.com