Luoyang Yujie Industry&Trade Co., Ltd is one of the most experienced manufacturers and suppliers of rotary kiln support roller for mine industry in China. Please feel free to buy cheap rotary kiln support roller for mine industry for sale here from our factory. All customized products are with high quality and competitive price.

Rotary Kiln Support Roller for Mine Industry

Products Description

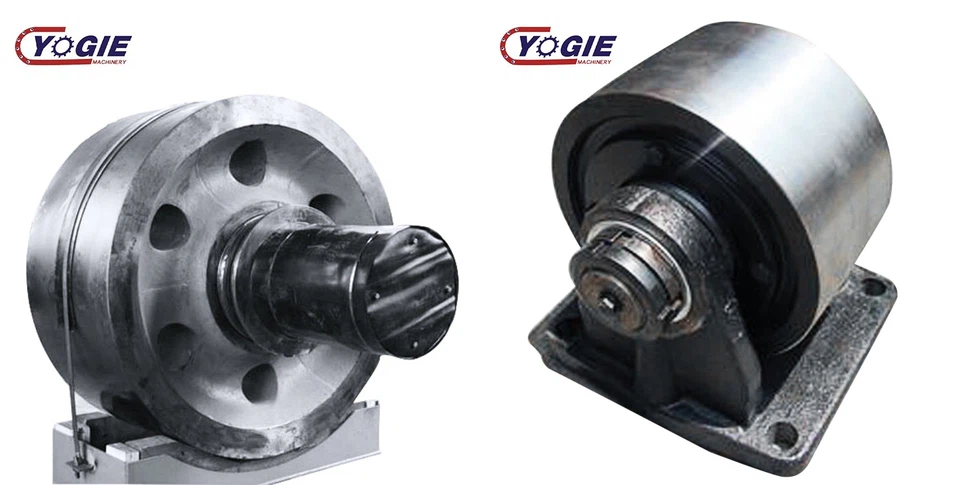

A rotary kiln support roller is a cylindrical component that helps to support the weight of the kiln and allow it to rotate smoothly. It is typically made of steel and is mounted on bearings that allow it to rotate around its axis. The support roller is an essential part of the rotary kiln, which is used to heatmaterials to high temperatures in order to cause a chemical reaction or physical change.

Products

|

Item |

Rotary kiln support roller |

|

Weight |

6-45T |

|

Material |

ZG35CrMo, ZG42CrMo, ZG340-640, etc. |

|

Used for |

Rotary kiln, ball mill, vertical roller mill, cement mill |

|

Application |

Cement, metallurgy, chemical, construction, etc. |

|

Standard |

ASTM, JIS, GOST, DIN, BS, WCB, etc. |

|

Certification |

ISO9001:2008 |

|

Heat treatment |

Normalizing, tempering, annealing, etc. |

|

Inspection |

Appearance, dimension, chemical composition, mechanical property, NDT(MT, UT, PT, etc.) |

|

Delivery status |

Rough machining; finished machining |

Machinery Processings

Material selection: The first step is to select the appropriate material for the support roller, which is typically steel or a steel alloy. The material must be able to withstand the high temperatures and heavy loads involved in rotary kiln operations.

Cutting: The steel material is cut into the required shape and size using specialized cutting machines. The accuracy of the cutting process is critical to ensure that the support roller is properly sized and shaped.

Turning: The support roller is then placed on a lathe machine and rotated while a cutting tool removes any excess material, creating a smooth and even surface. This process ensures that the support roller is perfectly round and of the required diameter.

Machining: The support roller is then subjected to various machining processes to create the necessary features, such as mounting holes and bearing surfaces. The machining process requires high precision and accuracy to ensure that the support roller fits perfectly with the other components of the rotary kiln.

Heat treatment: After machining, the support roller is subjected to a heat treatment process to improve its strength and durability. This involves heating the component to a specific temperature and then slowly cooling it to allow the material to harden and become more resilient.

Quality control: Finally, the support roller is subjected to rigorous quality control checks to ensure that it meets the required standards for strength, durability, and precision. The support roller is carefully inspected for any defects or imperfections, and any issues are corrected before the component is approved for use.

Contact us

Do you have any specific questions about the mining equipment parts? Contact Yogie! Our sales engineers will work with you from start to finish to ensure that your project is completed to your requirements.

Hot Tags: rotary kiln support roller for mine industry, manufacturers, supplier, factory, customized, cheap, price, in stock, for sale