Luoyang Yujie Industry&Trade Co., Ltd is one of the most experienced manufacturers and suppliers of double column machining center in China. Please feel free to buy cheap double column machining center for sale here from our factory. All customized products are with high quality and competitive price.

Products Description

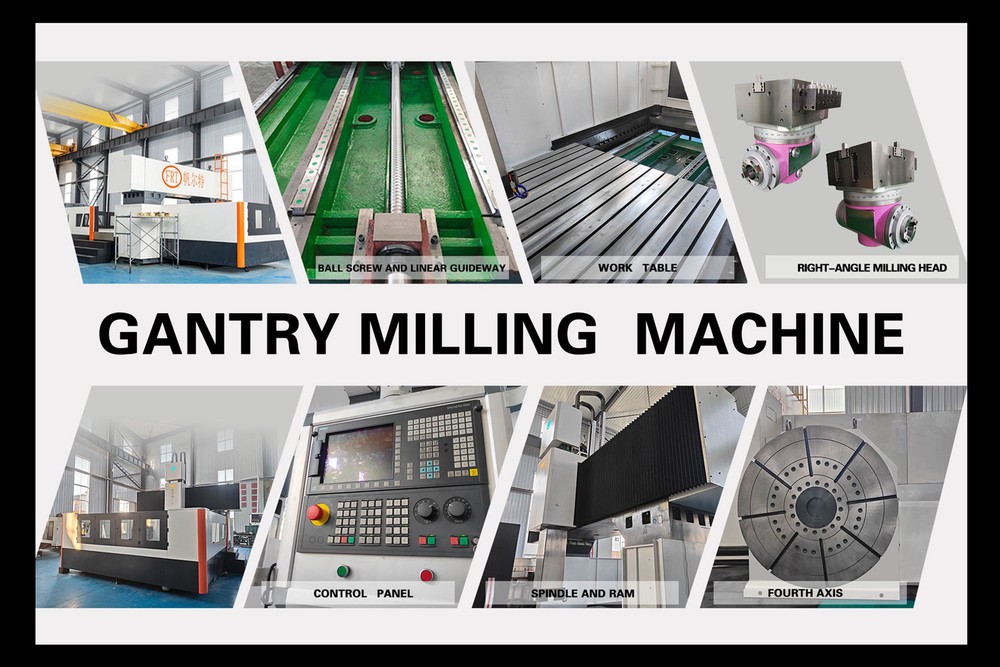

A double column machining center, also known as a bridge-type machining center or gantry machining center, is a type of machine tool used for precision machining of large and heavy workpieces. It is characterized by its rigid structure with two columns supporting the crossbeam or bridge that spans the working area. This design provides increased stability and rigidity, making it suitable for machining large and heavy components with high precision.

Products Description

FRT-6032

| Item | Main Parameter | |

| CNC operating system | SIEMENS | |

| Working table size | mm | 6000×2500 |

| Left and right stroke(X) | mm | 6000 |

| Back and forth stroke(Y) | mm | 3200 |

| Up and down stroke (Z) | mm | 1200 |

| Distance from spindle center to column guide | mm | 450 |

| Distance from spindle end to worktable surface | mm | 170-1170 |

| T-slot of worktable (Number/size/spacing) |

mm | 12-22×150 |

| Spindle taper(model/sleeve diameter) | BT50/Φ190 | |

| Use pull stud modle | P50T-1 | |

| Spindle Speed(rpm) | rpm | 6000 |

| X axis ball screw specifications | mm | 100×16 |

| Y axis ball screw specifications | mm | 80×12 |

| Z axis ball screw specifications | mm | 63×10 |

| Machine tool positioning accuracy (GB/T 20957.4-2007 standard) |

mm | 0.01 |

| Repeated positioning accuracy of machine tools (GB/T 20957.4-2007 standard) |

mm | 0.01 |

| X/Y/Z axis rapid shift | m/min | 10/12/10 |

| Cutting speed | m/min | 7 |

| Spindle transmission mode | Synchronous toothed belt drive | |

| XYZ axis servo motor transmission mode and transmission ratio | X-axis reducer directly connected 4:1; YZ directly connected transmission Y-axis 1:1,Z-axis 1:1 |

|

| X,Y axis guide specifications | X-axis four 55-gauge heavy-duty roller linear guides; Y-axis three 55-gauge heavy-duty roller linear guides |

|

| Z axis guide specifications | Rectangle hard rail | |

| Square Ram Size | mm | 600×600 |

| Spindle power | KW | 35 |

| Recommended selection of servo motor parameters | N·M | 79/45/40 |

| Air source flow | >0.5 | |

| Power supply requirements | 380V | |

| Bed cushion height | mm | 30 |

| Workbench load bearing | kg | 30T |

| Machine dimensions | mm | 16000×5500×4000 |

| Light machine net weight | kg | 75t |

options

Features of double column machining center

Stability and Rigidity: The double column structure enhances the stability and rigidity of the machine, ensuring high precision and accuracy in machining operations.

Large Working Area: Double column machining centers typically have a large working envelope, making them suitable for machining large workpieces. The spacious work area accommodates a variety of part sizes.

High Load Capacity: These machines are designed to handle heavy workpieces, and the double column structure provides excellent support for the machining process.

Versatility: Double column machining centers are versatile and can be used for various machining operations, including milling, drilling, tapping, and other precision machining processes.

High Cutting Performance: The rigidity of the machine allows for high cutting performance, enabling efficient material removal and faster machining speeds.

Automatic Tool Changers: Many double column machining centers are equipped with automatic tool changers, allowing for the use of multiple tools in a single machining setup, reducing downtime for manual tool changes.

Functions and applications

Milling: Double column machining centers are used for milling operations, including face milling, contour milling, and 3D surface machining.

Drilling: The machines can perform precision drilling operations on large and complex workpieces.

Tapping: Tapping, or thread cutting, can be carried out with precision using these machining centers.

Mold and Die Making: The stability and accuracy of double column machining centers make them well-suited for mold and die making in industries such as automotive and aerospace.

Aerospace Components: These machining centers are commonly used for machining large aerospace components, such as aircraft wings, fuselage parts, and engine components.

Automotive Parts: In the automotive industry, double column machining centers are employed for the production of large and complex components, such as engine blocks and transmission housings.

Heavy Machinery Components: Industries involved in the manufacturing of heavy machinery, such as construction equipment and industrial machinery, use double column machining centers for machining large and heavy components.

Energy Sector:In the energy sector, such as the production of turbine components for power generation, Double Column Machining Centers play a vital role. They can handle the machining of large and heavy components required in power plants.

Railway Industry:For the manufacturing of large and durable components used in the railway industry, such as locomotive parts and rail components, Double Column Machining Centers are employed to ensure precision and reliability.

General Heavy-Duty Machining:Any application that involves heavy-duty machining of large components can benefit from Double Column Machining Centers. This includes tasks like milling, drilling, and boring operations on materials like steel, cast iron, and other metals.

High-Volume Production:When there is a need for high-volume production with consistent precision, Double Column Machining Centers can be utilized. The robust design and stability of these machines contribute to maintaining accuracy over extended production runs.

Complex 3D Contouring:Double Column Machining Centers equipped with advanced CNC controls are capable of performing complex 3D contouring operations. This makes them suitable for tasks that involve intricate shapes and profiles.

Hot Tags: double column machining center, manufacturers, supplier, factory, customized, cheap, price, in stock, for sale